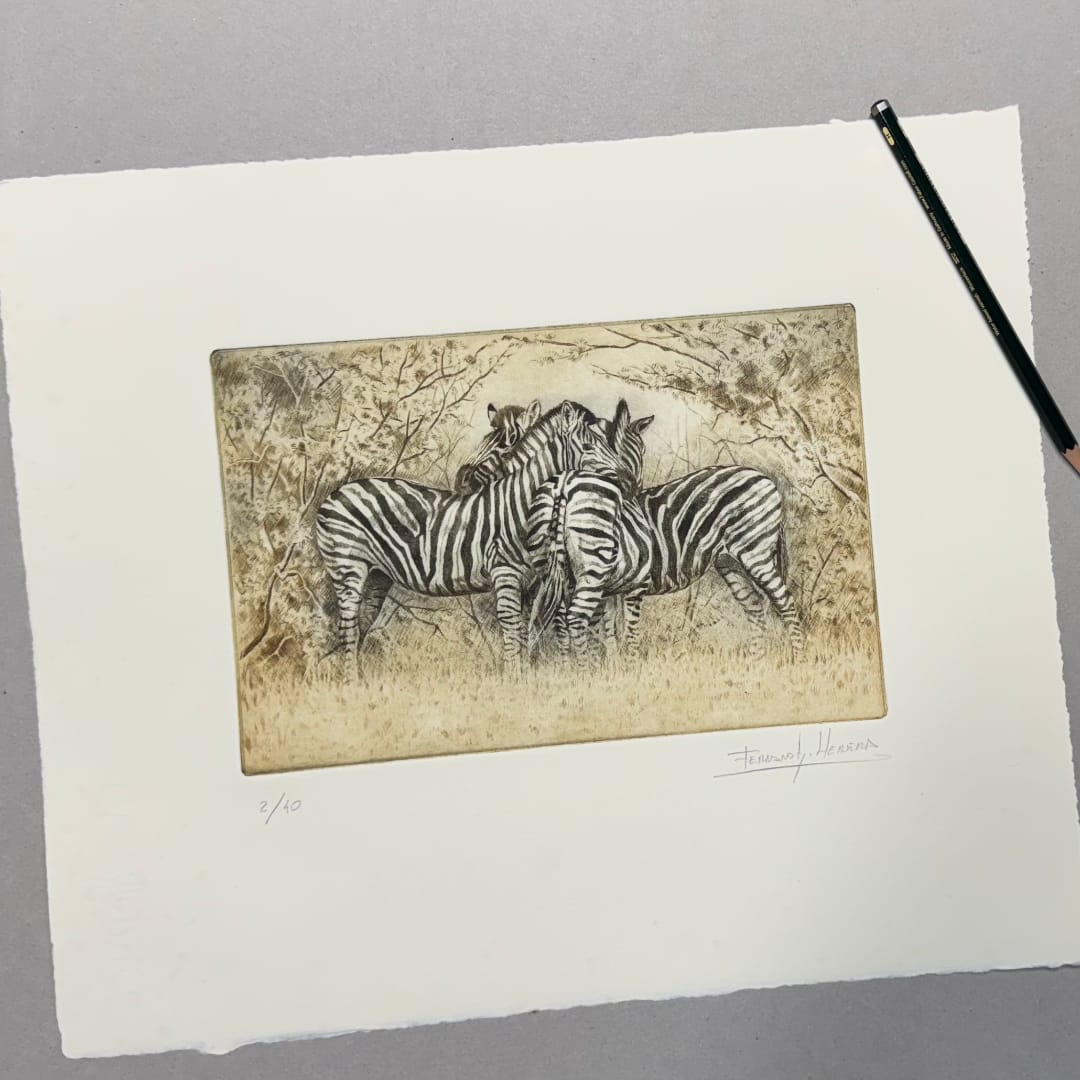

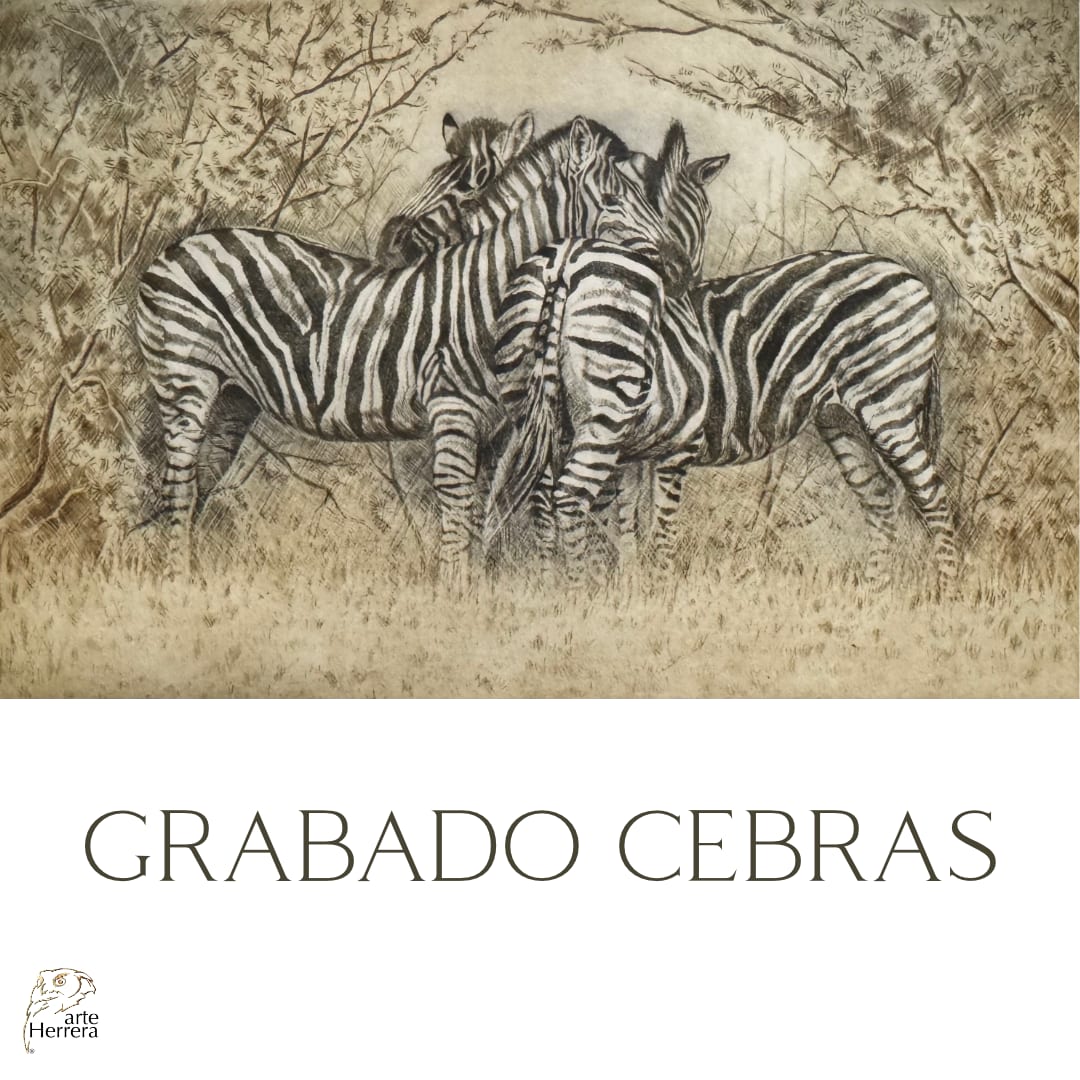

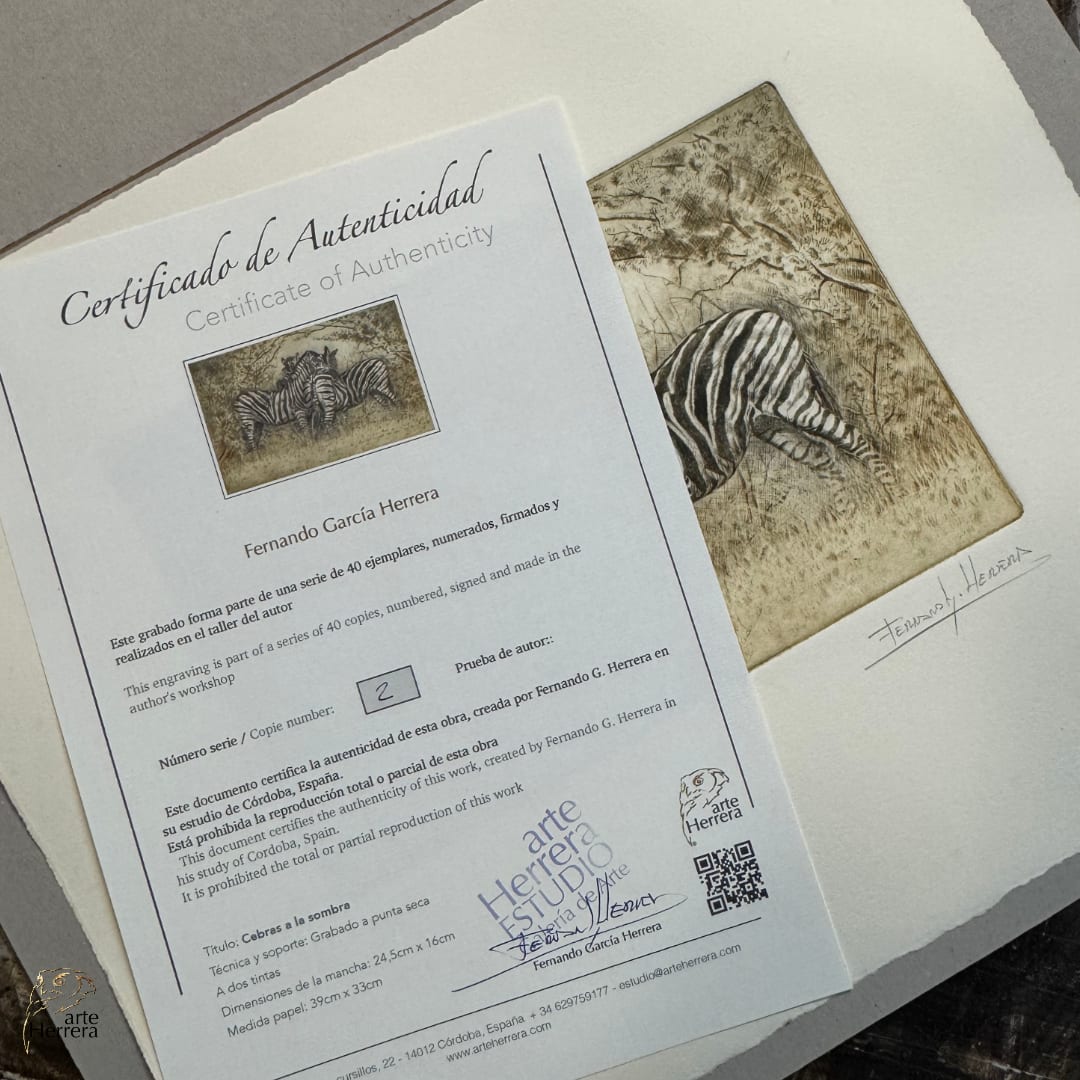

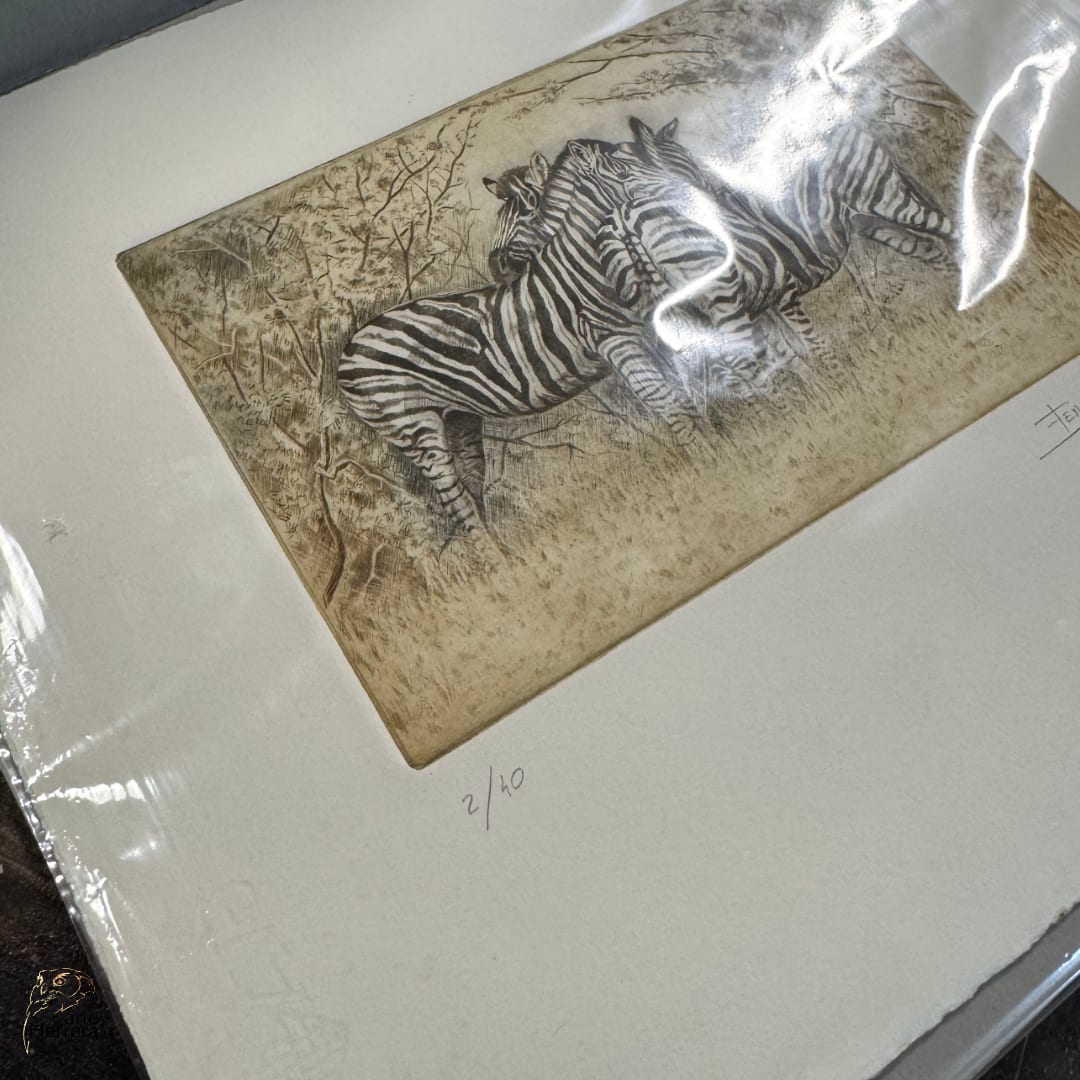

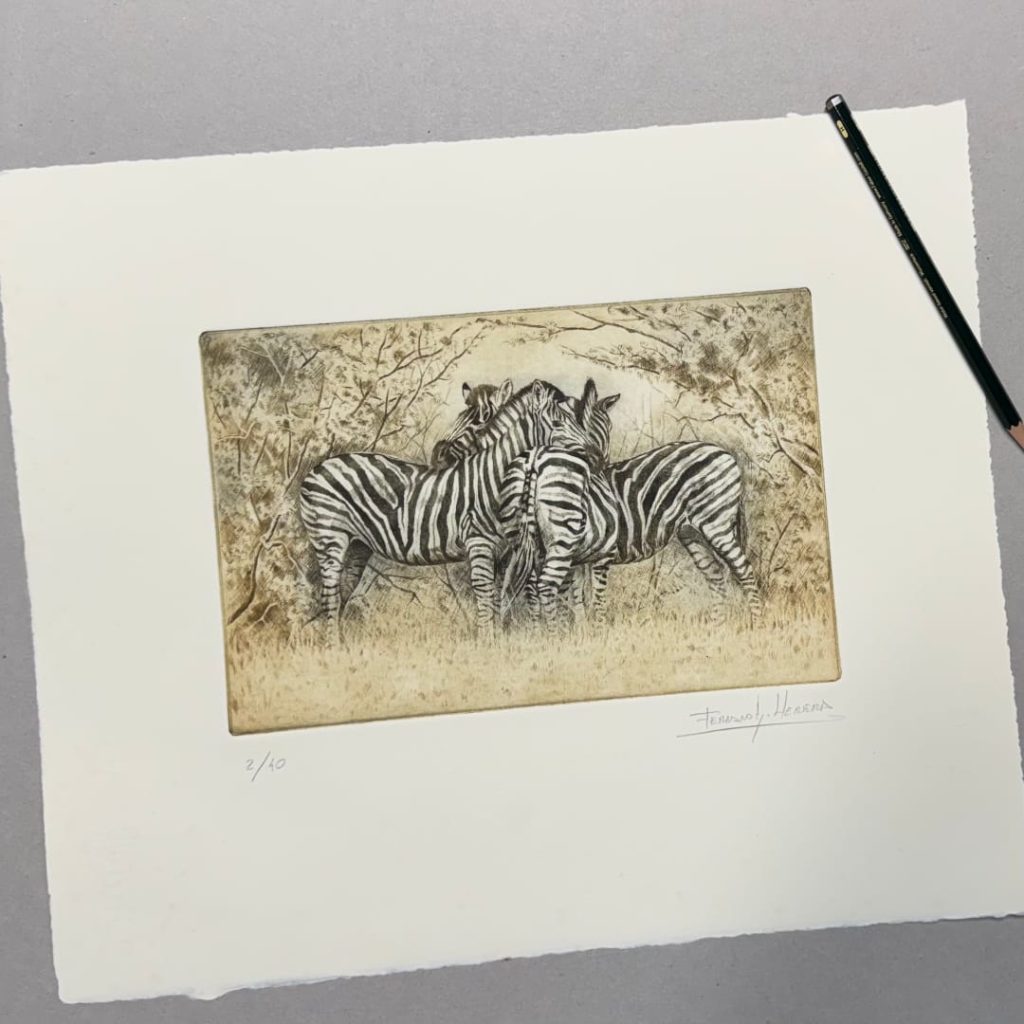

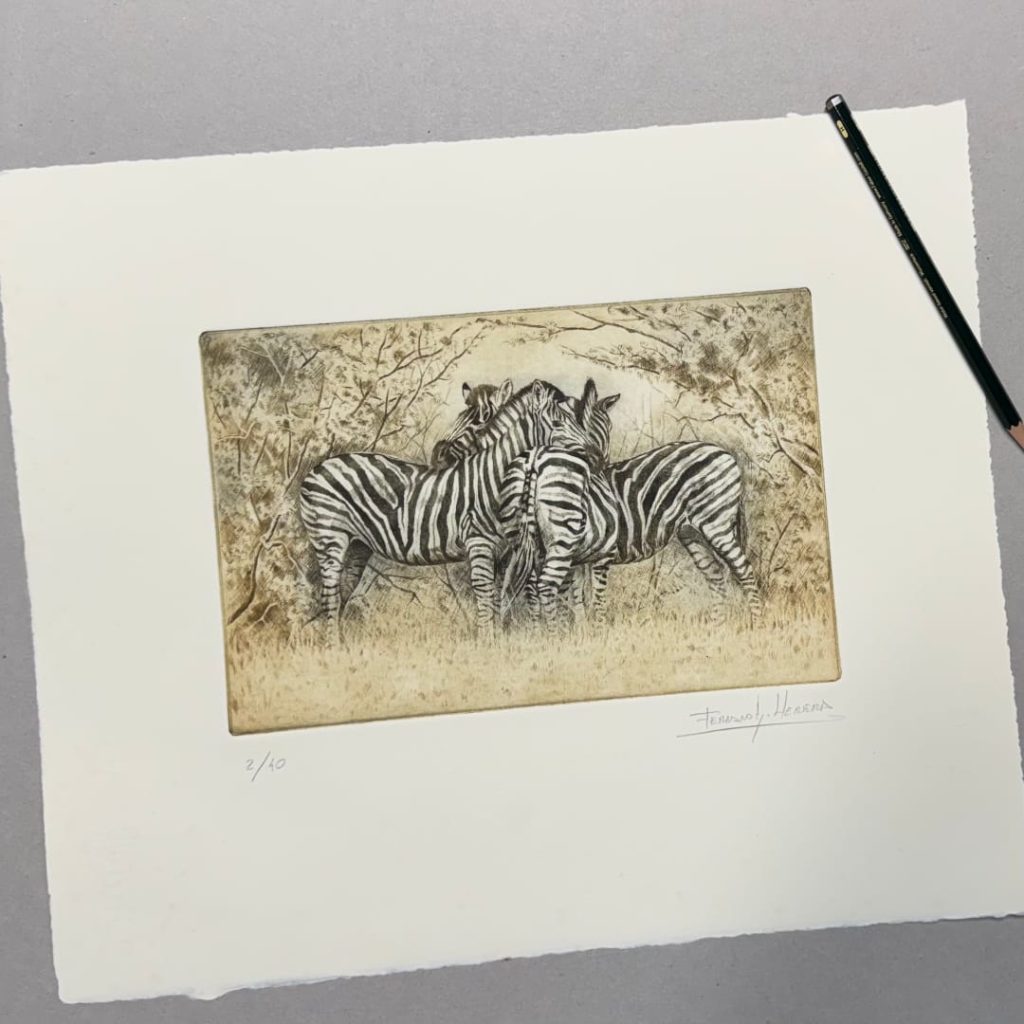

Original zinc plate engraved by Herrera

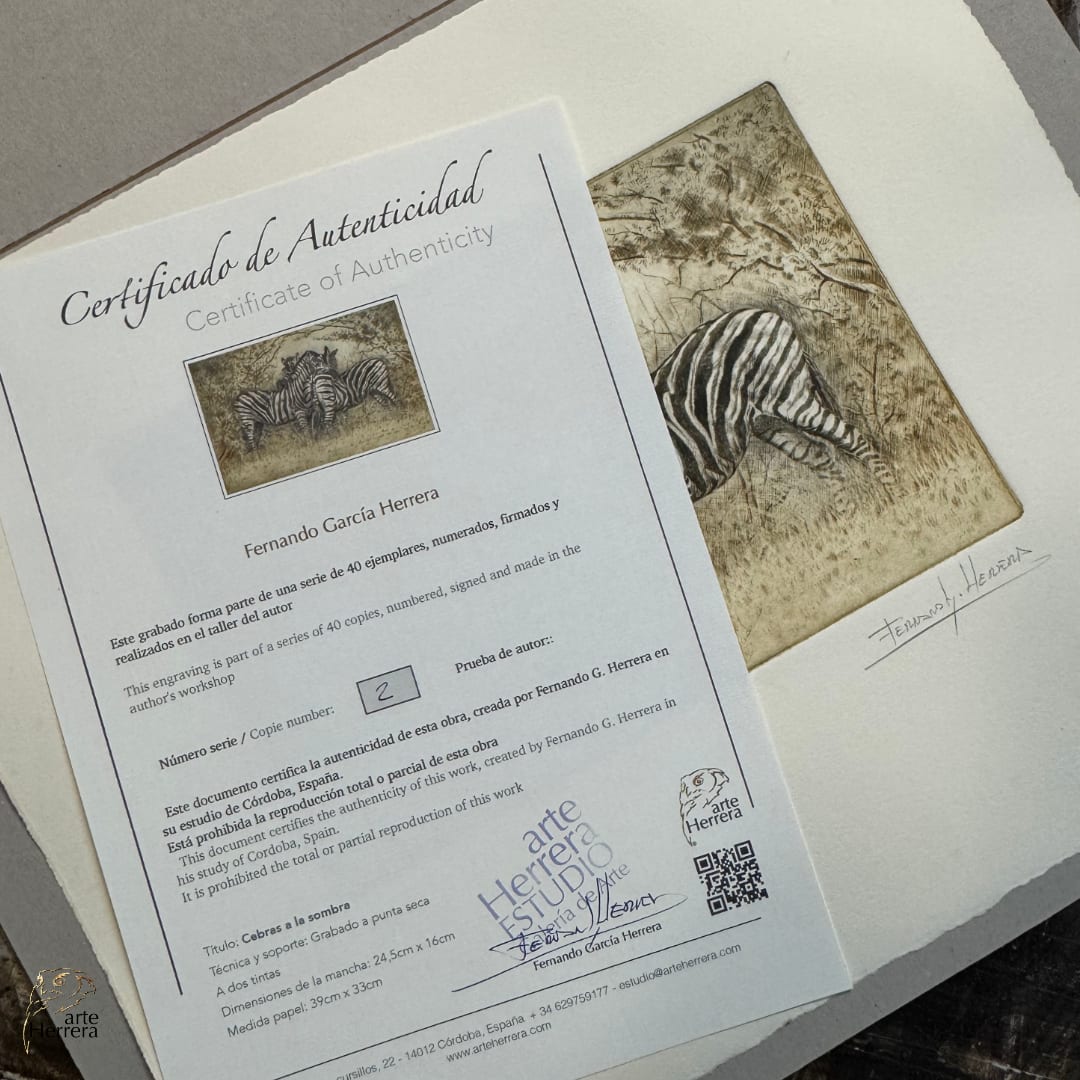

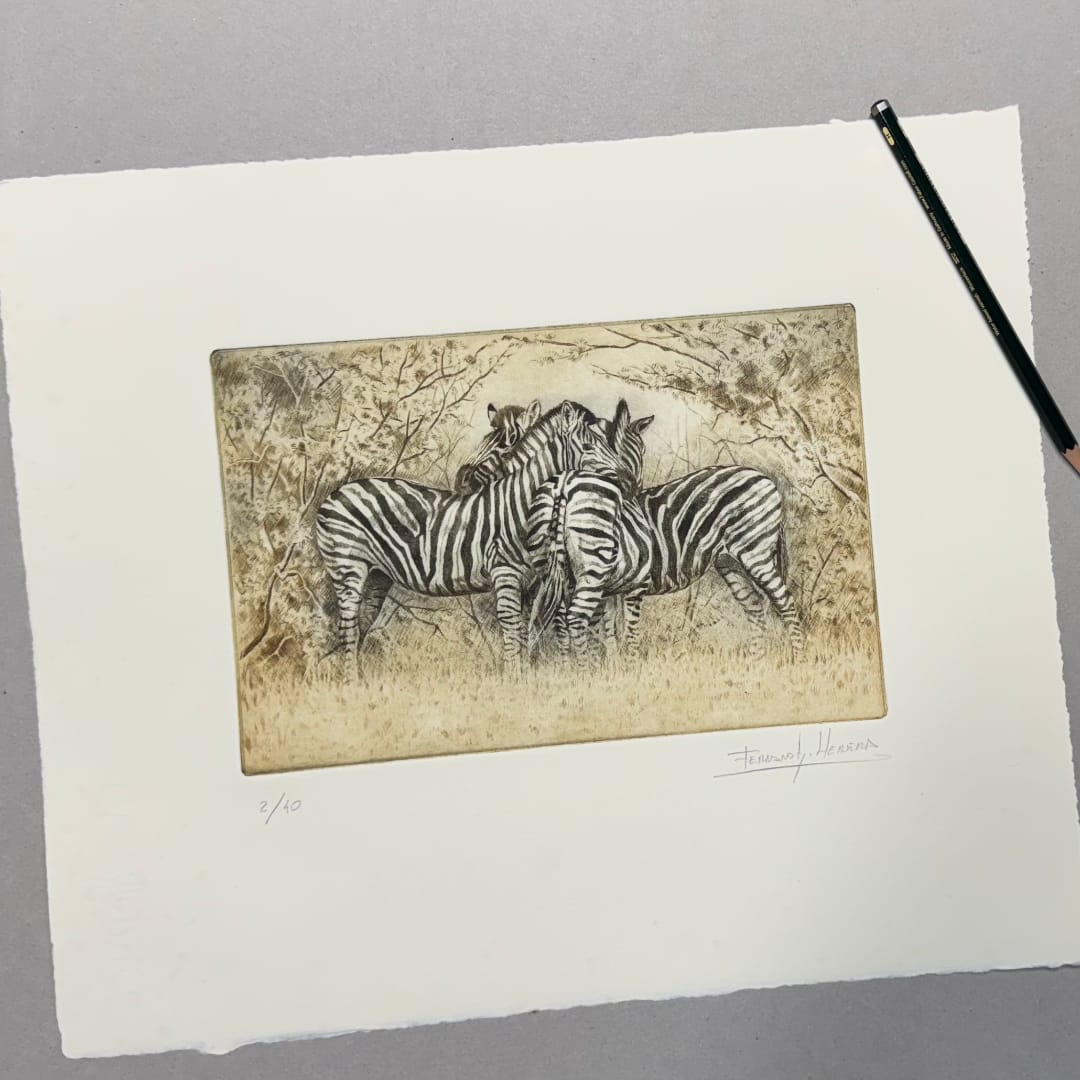

Printed in the artist’s own workshop, guaranteeing the strict and exclusive numbering of this engraving.

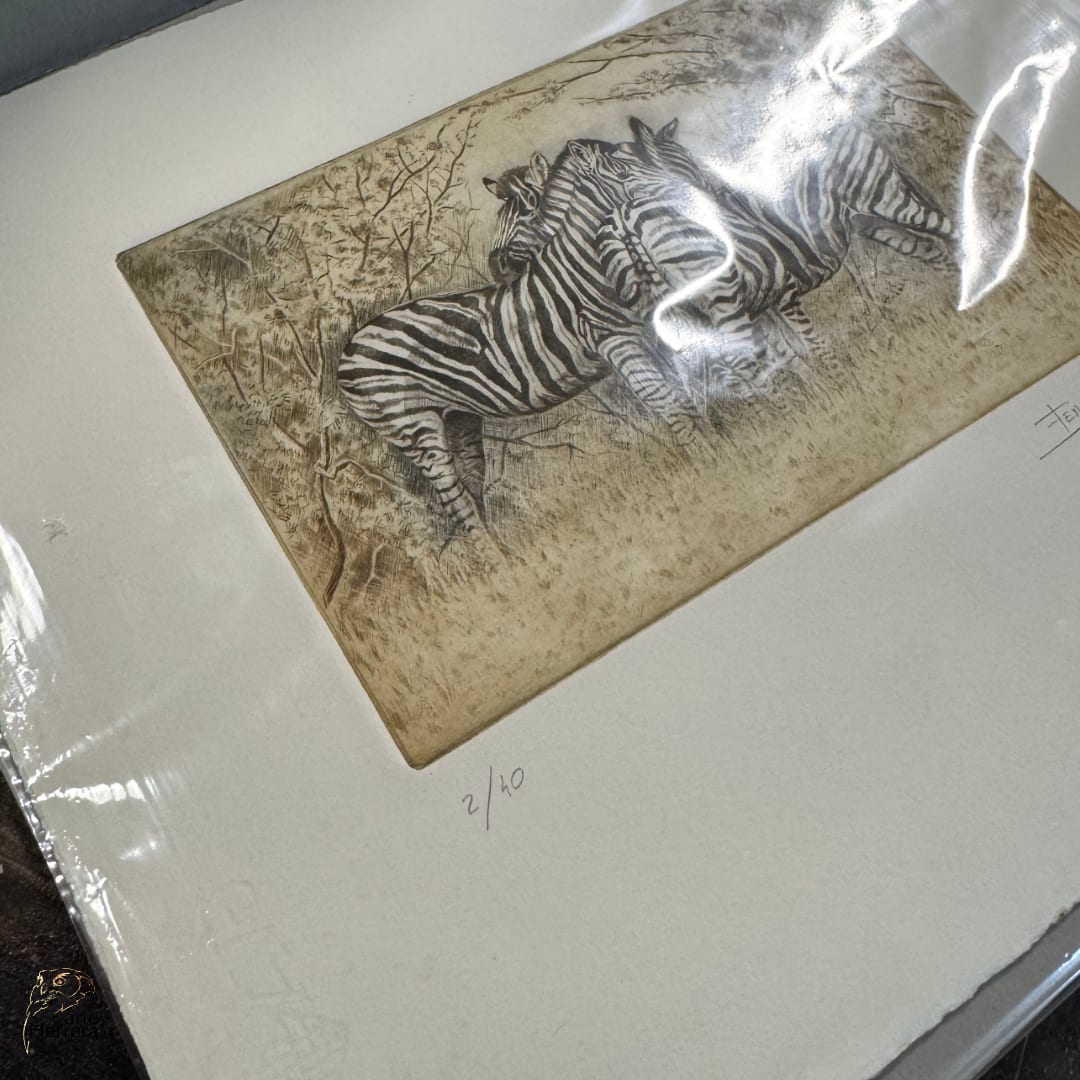

The engraving is delivered in a custom-made rigid folder, which includes the engraving protected by a film, and the corresponding certificate.

We never ship engravings rolled up; they are always shipped in a folder and with special packaging to ensure their safe arrival.

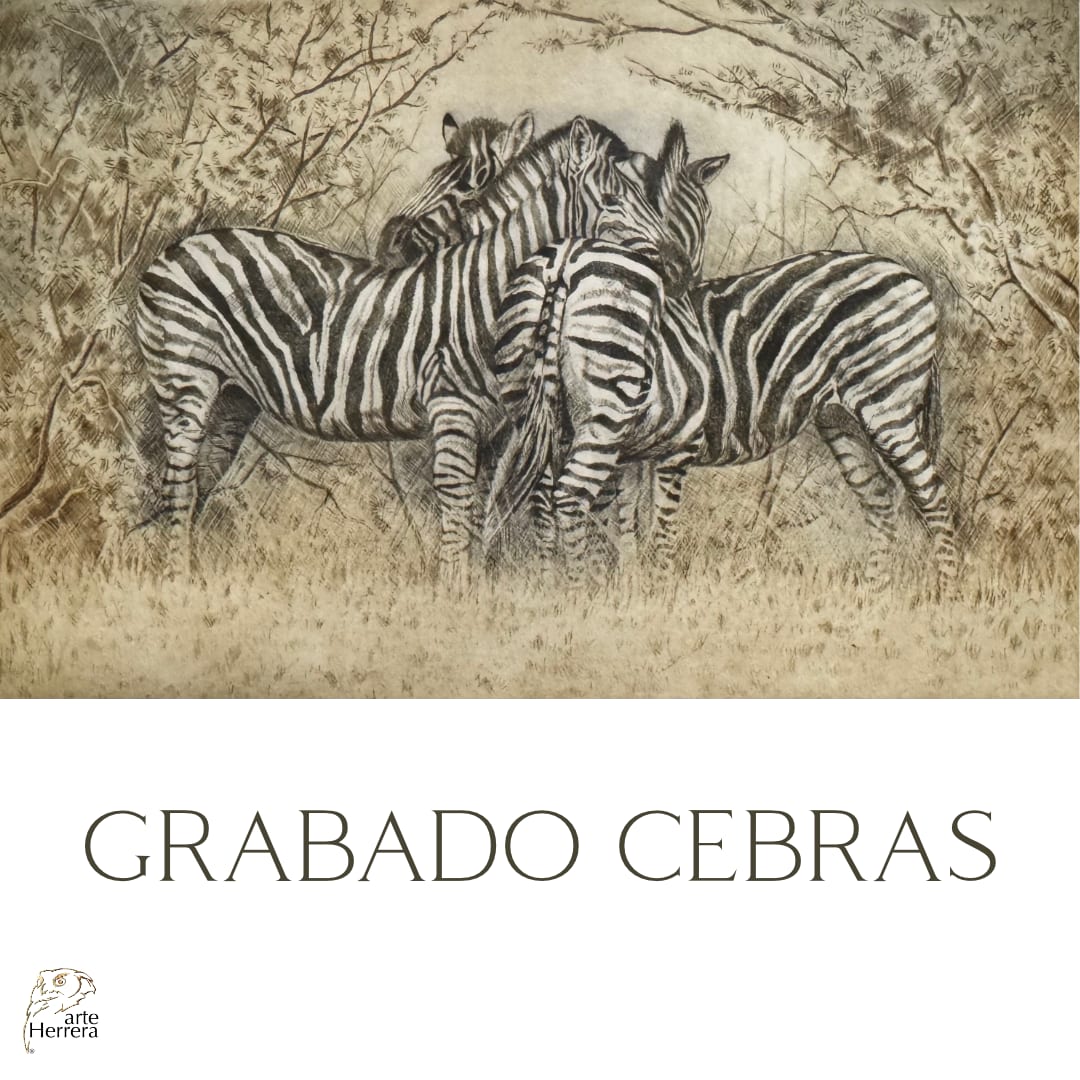

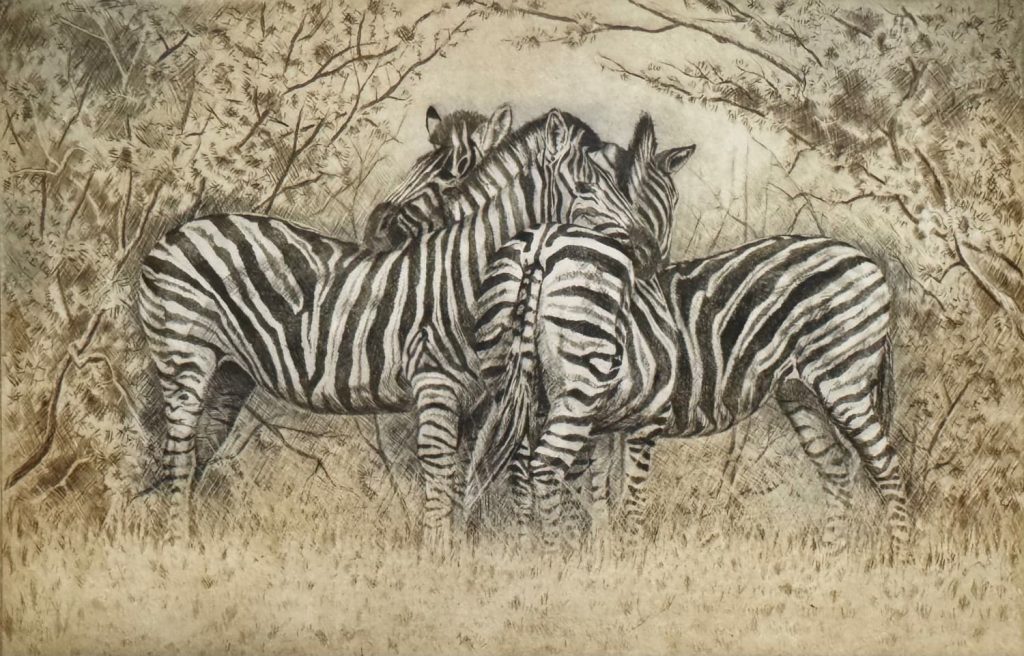

La elegancia de un grabado

Learn more about drypoint engraving:

History

The technique has been known since the Renaissance, when it may have been developed by the Master of the House of the Book, a nickname given to a still-unknown painter and graphic artist who worked in southwestern Germany, near Mainz, between the 15th and 16th centuries. This artist produced works using this previously unknown technique. Drypoint was a technique of free expression in the 17th and 18th centuries, sometimes looked down upon by publishers due to its lower profitability compared to the burin. Rembrandt was an enthusiast of it, unlike Dürer, who used it in three works. In the evolution of Rembrandt’s printmaking, drypoint was integrated into the printing plates, in many cases becoming predominant and in others ultimately the primary technique. This aspect of drypoint, which complements other processes, should be emphasized, since its direct and emotive execution allows for subtle nuances or highlights in any print made with another technique.

Technique

The artist draws the image on an untreated zinc plate using a pencil-like instrument with a diamond point or simply a sharpened metal tip. As the incision is made, a groove is created, raising soft metal ridges called “burrs” or “flakes” on either side. Burrs can occur on one side of the line or groove, or on both sides, depending on the angle of attack (the tilt of the tip) relative to the surface. If working at an angle of approximately 45°, the burr will form at the complementary angle. If working at about 90°, with the tip perpendicular to the surface, burrs will appear on both sides of the line.

These burrs retain a certain amount of ink and give the drypoint line a rich, velvety appearance. However, for a crisp, clear look, it is best to remove the burrs without damaging the groove. The burrs are delicate and wear down with the continuous pressure of the press, so print runs are limited to no more than 80 copies.

Stamping and drypoint printing are done by inking the sheet, cleaning it, placing a dampened paper over it, and inserting it into the press.